PREPAC® Advanced

- with the latest pre-impregnated wet cloth technology

PREPAC Advanced delivers the fastest wash and the lowest start-up waste on the market.

Increased production time

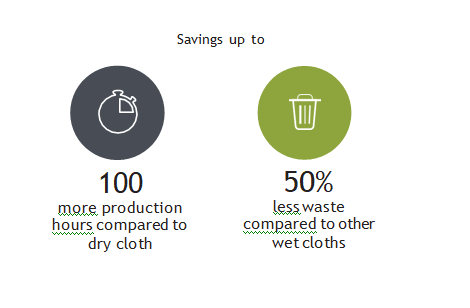

The wash time is significantly reduced by up to 25%, leading to minimi- zed downtime and increased productivity with up to 100 additional production hours per year.

Reduced start-up waste

Up to 50% reduction of wasted copies during start-up and it effectively eliminates any toning and dripping after the wash.

Voice of the customer

”Since we started to use PREPAC Advanced, there are no more challenges with time consuming manual cleaning, toning, fluff on the impression cylinder or dripping on the plate. The high cleaning efficiency enables shorter wash programs which results in reduced downtime and of course more production time.”

Mr. Ensun Ylimer, DUMA Druck GmbH

Baldwin’s unique capabilities

Best in Class Cleaning

Consistent cleaning results

Optimized formula

Customized solution

Eco Friendly

No handling of solvent

Non-VOC solvent

Less consumables waste

Increased Production Time

Faster cleaning

Shorter make ready time

Less service & handling

”All in one”

Full product support

Field engineering

Process know-how

PREPAC Advanced is available for conventional, UV and rough cylinder applications. Option for PREPAC Advanced: Baldwin Water Boost, which is developed exclusively for PREPAC Advanced and increases the cleaning performance while enabling 100% water spray.

The new PREPAC Advanced cloth benefits

Less cloth consumption: Due to new more efficient solvent and cloth.

Lint free: No loose fibers on the blanket after the wash.

Higher cleaning effect: Due to new more efficient solvent and new cloth with high absorption and abrasive surface.

Improved stability: Eliminates all kinds of necking in, folding and wrinkles.

High absorption capacity: Enables high speed picking of ink and lint.

Faster and higher release of cleaning agent: Enables quick dilution of ink on the blankets.

All above result in a faster wash and very low start up waste.