JUST LAUNCHED: Introducing PVQ 4.0 - Meet your new printing inspection software that takes the complexity out of your printing jobs, and puts in the magic.

Baldwin Vision Systems print inspection and defect tracking workflows make it possible to eliminate all defects from outgoing product, providing perfect quality to brand owners. It’s possible to make tactical decisions—based on facts—about which defects do and do not need to be removed, based on your customers’ specifications. This ensures maximum yield and maximum profitability—job after job.

For advanced print inspection solutions, ease of use is an important consideration for quickly deploying new technologies and realizing a fast return on investment. Systems that require very little training to operate will benefit the bottom line not only when the technology is installed, but also far into the future as workforce turnover impacts the business. Aside from a reduced need for training, print inspection workflows that are powerful yet simple to use deliver a day-to-day boost to production efficiency and increase your ability to achieve perfect print quality.

There are large operational and competitive advantages to be realized by committing resources and organizational focus to delivering consistent print quality. Investment in the latest automation and data-connected print inspection technologies can quickly pay for itself and provide significant bottom-line growth far into the future.

for Wide Web

Defender® View

For typical packaging print applications and other niche applications.

Easy, smart, and future-proof web monitoring for the print industry.

Defender® 100% Inspection

For Packaging & Converting applications.

Monitors the entire web 100% of the time to detect and manage defects such as spots, streaks, color shifts, haze, wrinkles, pinholes, contamination, and any other random defects.

Defender® Data Central®

For Packaging & Converting applications.

Monitors, audits, stores and generates reports of both live and historical data to optimize quality control.

Defender® Waste Manager

For Packaging & Converting applications.

Automated control for optimized waste removal.

Web Viewing System

For Packaging & Converting applications.

Superior image magnification and clarity make it possible to see the tiniest detail, and catch defects before they become costly problems.

for Label, Narrow- and Mid-Web

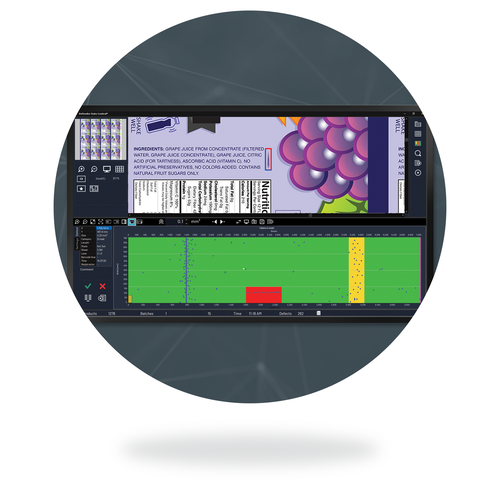

Guardian PQV 100% Print Inspection

For Packaging & Converting, Security Printing applications.

Provides complete print quality verification from prepress through production, reporting, and archiving.

Guardian RTM Real-Time Monitoring

For Packaging & Converting, Security Printing applications.

Monitor changes as they happen, and make highly-informed decisions about print quality, defect management, and even operator-to-operator performance.

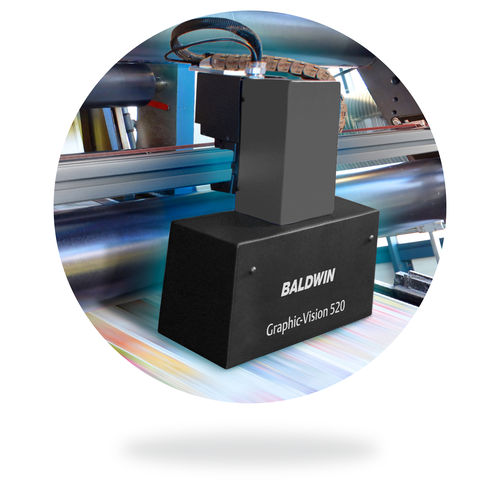

Graphic-Vision® 500-Series Web Viewers

For Packaging & Converting applications.

Utilizes high-resolution digital cameras and modern LED lighting for longer life, greater reliability, and lower cost.

Offline Proofing & Inspection

Guardian OLP Offline Proofing & Inspection

All applications.

Compares any pre-press file or scanned press sample to the customer-approved original in a matter of seconds,