Baldwin is known in the printing industry for its automatic blanket cleaning systems, which achieve unmatched cleaning results - especially when paired with the proper consumables.

The company is proud to offer key solutions that printers know and rely on, via its Impact Fusion product lineup.

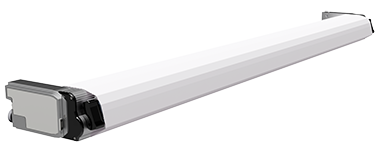

Impact Fusion NP™ - for Newspaper and Semi-Commercial Presses

This system offers a reliable, time-saving way to automatically clean the blankets used for printing newspapers and other commercial work, saving time, resources and money - setups work for both heatset and coldset applications.

How It Works:

The Impact Fusion-F NP cleaning system for newsprint and other commercial printing applications uses a compact cleaning module, installed in the press, to clean blankets automatically whenever required. Cleaning cycles are short and efficient, increasing production times while reducing waste.

Noteworthy Benefits:

Systems require minimal maintenance, and offer long service intervals

Full coldset and heatset capabilities in all wash modes

Simple, elegant design offers high reliability

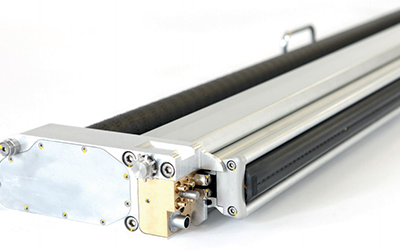

Impact Fusion CW™ - for Web Offset Presses

Designed for web offset printing, this system cuts the time it takes to accomplish blanket cleaning in half by automating the process. Systems are engineered for high-speed printing, and virtually eliminate the risk of web breaks.

How It Works:

Systems use a roll-cloth-based cleaning module, paired with a precision spray application system that spans the width of the web, to clean blankets while they are still on press. Operators use a simple touchscreen interface to control cleaning cycles, which deliver optimized cleaning with any print job, without the operator needing to program in changes to achieve desired results.

Noteworthy Benefits:

Systems provide even and secure cleaning results, without leaving streaks on blankets

Blankets are clean in 5 to 15 seconds with “Impression On” cleaning mode, and in 15 to 30 seconds with “Impression Off” cleaning mode

Cloth rolls change easily, without tools