Industrial 3D LED UV Curing

LED UV light has moved into the mainstream in industrial manufacturing as the preferred process to instantaneously cure UV-light-reactive adhesives, coatings and finishes for superior bonding, sealing, coating and finishing on substrates of all kinds.

Its application is widespread in the automotive, medical device, electronics and consumer goods industries to name a few, for products of all kinds, ensuring perfect curing, even at top production speeds, as they roll off the assembly line.

A major challenge for industrial manufacturers is completely curing objects in three dimensions. Since 3D objects have a significantly greater mass than flat objects and surfaces, they require a larger chemistry quantity to complete the curing reaction, meaning a larger UV dose.

Another challenge with curing 3D objects is the irradiation distance of UV light. In order for an object to be fully cured, every point on it must be in the line of sight of the UV radiation, while also receiving proper irradiation intensity. With a standard LED lamp, this is virtually impossible, as the UV light disperses widely, resulting in a steep drop-off in irradiation intensity just millimeters away from the lamp’s surface.

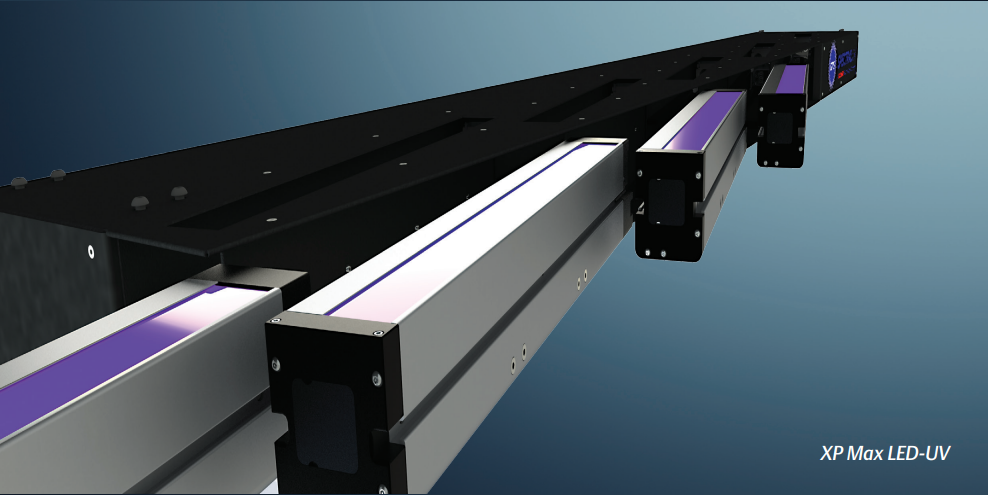

Utilizing a patented optical system, Baldwin’s XP LED UV series provides a unique solution to effectively cure 3D objects. Now, manufacturers can expect a complete cure, while also reaping the many benefits of utilizing LED technology.

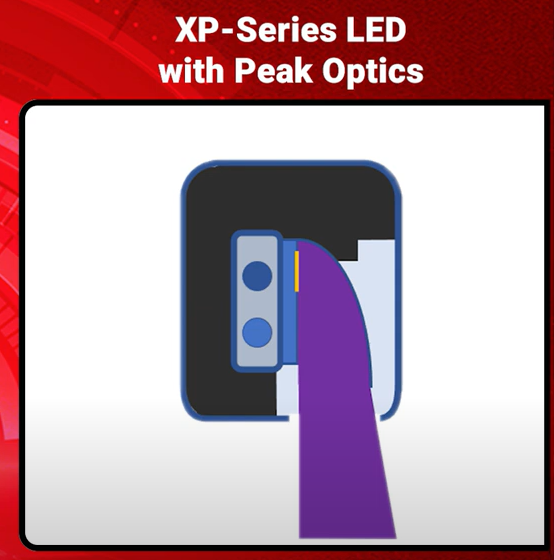

A standard LED lamp fires UV light directly downwards. The XP series, on the other hand, brandishes a “side-fire” optical system. The UV light is fired sideways at a parabolic reflector, which then reflects the light downward in a concentrated beam.

This light beam maintains upwards of 90% of the peak intensity as far as 1 inch away from the lamp, and even upwards of 60% of peak intensity 2 inches from the lamp. With these capabilities, the XP Series can effectively meet the demands of curing 3D objects.

Taking it a step further, Baldwin’s XP Quatro Series houses two powerful LED arrays, delivering double the power of a standard LED lamp, while remaining a lower cost than two individual lamps. The Quatro Series can effectively cure objects as far as 6 inches away, making its capabilities virtually limitless.

The XP series boasts a small form factor while maintaining a high-power output. It also provides all the advantages of LED curing, including fast and uniform curing, instant start-up/shut-down, stable energy output, low heat emission, and low energy consumption.

For a deep dive, watch Why Side Fire Reflection is the Next Big Thing in Industrial LED UV Curing