Baldwin manufactures and supports conventional UV curing solutions via its market-leading division, AMS Spectral UV®.

The company offers two key UV curing solutions: QuadCure and Titanium UV, both of which are ideal for printing and other industrial applications.

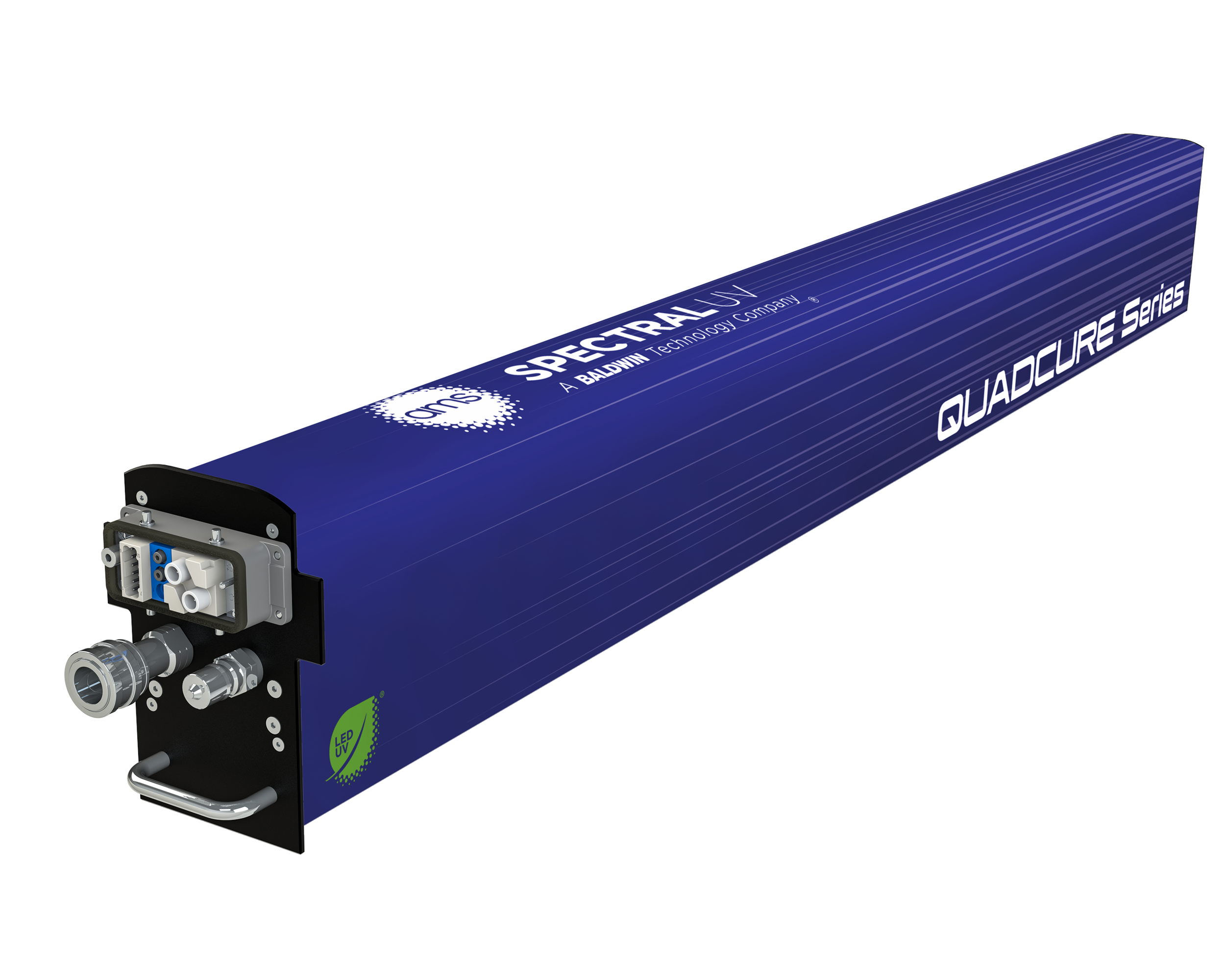

QuadCure UV - For Printing and Industrial Applications

QuadCure offers an elegant solution for curing UV inks and coatings as part of commercial printing processes. It offers printers the ability to use UV coatings and effects to create high-value specialty work.

How It Works:

The most reliable arc-lamp-based UV curing solution, QuadCure is ideal for printers looking to achieve perfect curing with minimal power consumption.

Each system is designed to make lamp changes easy, and an array of upgrade options are available, including a low-heat setup.

Top and dedicated side reflectors help QuadCure lamps securely cure from varied distances, and a single quick-release plug for the power and control system simplifies operation and maintenance.

This system is ideal for printers seeking an elegant but heavy-duty curing solution for offset printing, as well as for curing coatings for high-graphics corrugated printing.

Noteworthy Benefits:

Flexible designs are made for different applications

UV lampheads are shuttered

Energy-saving dichroic reflectors come standard

Exceptionally compact design features quick-release couplings and a single quick-release plug for power and control connections

1000s of Quadcure units are installed worldwide

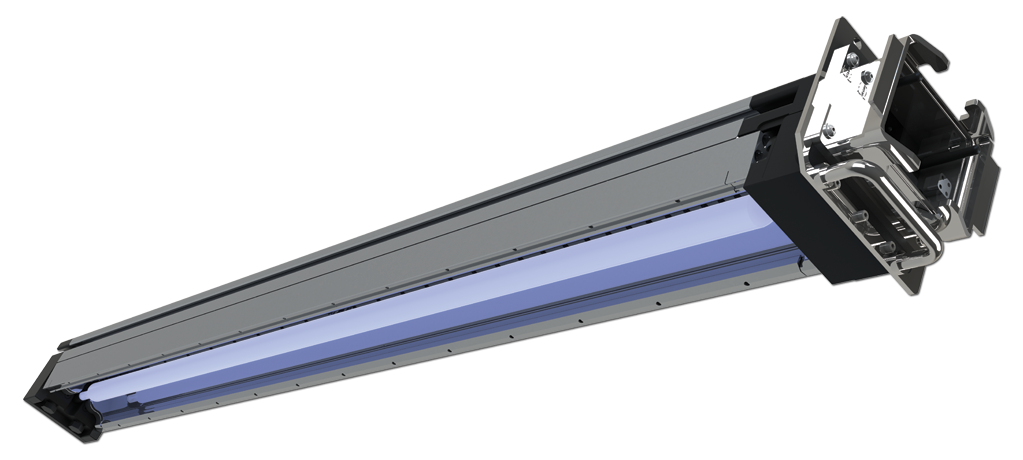

Titanium UV - For Printing and Industrial Applications

Titanium UV offers the top-of-the-line solution for offset printers seeking an efficient and ergonomic conventional curing system.

How It Works:

Ergonomically designed to slide easily onto and off of the press, the Titanium UV curing system offers best-in-class curing for a conventional UV setup. A favorite of printers everywhere, this best-selling system is based on AMS Spectral UV's legacy P3 UV curing line, and represents its most advanced and functional rendition of that classic system.

Titanium systems work with multi-color sheet-fed offset presses from Heidelberg, KBA, Komori, manroland, Mitsubishi, Ryobi, Akiyama, Sakurai and others, as well as web offset and flexo presses from most manufacturers.

Noteworthy Benefits:

reliable water-cooled system

self-healing shutters that guarantee realignment of reflectors

seamless water circuits that eliminate rubber hoses

mechanical parts are separated from module body to ensure no parts fall into the press

can be changed, cleaned and checked quickly and easily, without tools

100% electronic ballasts