Eliminate the pain of wrap-ups after web breaks on web offset presses with Baldwin’s innovative WebCatcher system.

This press-protection solution reliably prevents wrap-ups after a web break, and works with web offset presses running top speeds.

How It Works:

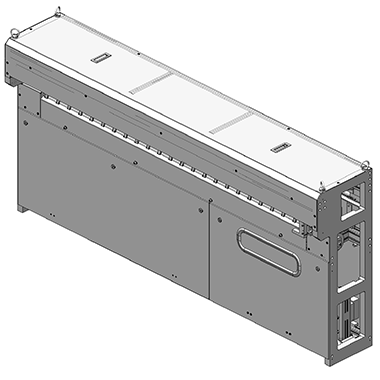

Baldwin’s WebCatcher is a press protection system that reliably prevents wrap-ups after a web break. The fully integrated automatic web catching system works with web offset presses running speeds of up to 18 meters per second, and can be easily retrofit to existing presses. With a small footprint, units are installed between the last printing unit and the dryer.

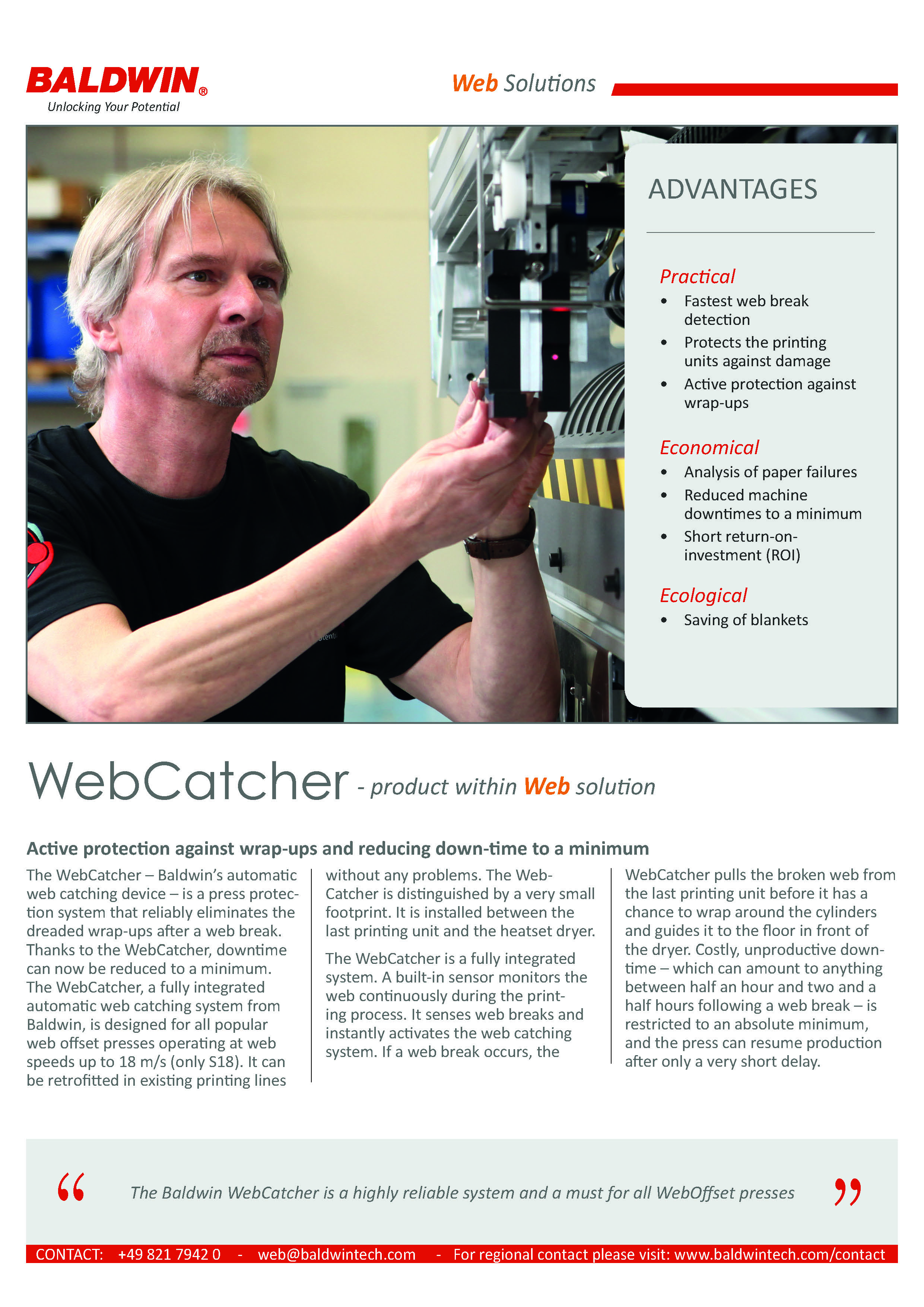

In operation, a built-in sensor monitors the web continuously during the printing process. This sensor detects web breaks, and instantly activates the web-catching system when a break is detected.

If a web break occurs, WebCatcher pulls the broken web from the last printing unit before it has a chance to wrap around the cylinders.

Noteworthy Benefits:

WebCatcher hugely reduces downtime associated with web breaks - what used to take half an hour or more now takes only minutes to rectify

WebCatcher protects your web offset press against damage caused by web break wrap-ups

Systems offer a very short ROI