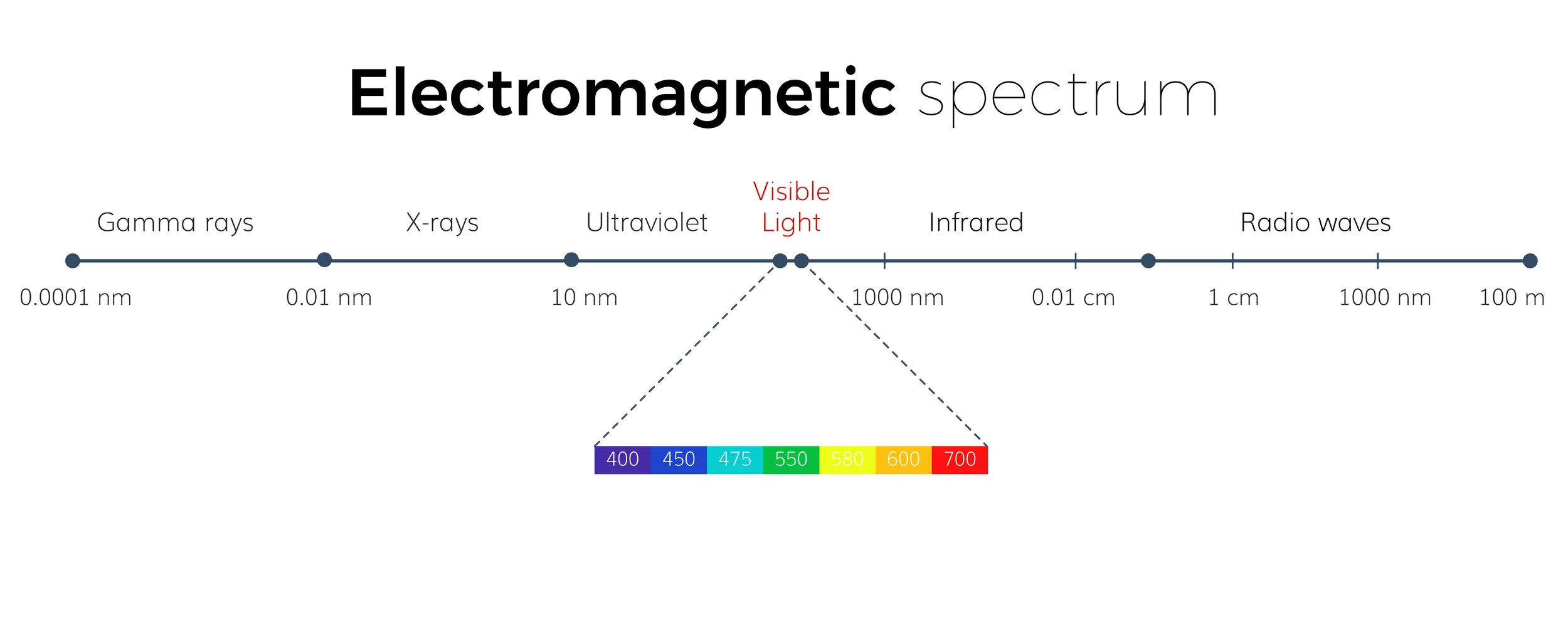

Infrared drying is an indirect method of drying water-based inks or coatings that does not rely on an intermediate such as air or water. The process typically involves a transfer of radiation energy from a hot element contained within an IR lamp to a lower temperature substrate. Thermal radiation between 0,78 µm, and 1000 µm on the electromagnetic spectrum is considered to be Infrared.

A look at where Infrared falls on the electromagnetic spectrum

Infrared radiation is generally split into 3 main categories.

· Short-wave IR (SW): from 0,78 µm to 2µm

· Medium-wave IR (MW): from 2µm to 4µm

· Long-wave IR (LW): from 4µm to 1000µm

For typical water-based printing applications, short or medium-wave IR drying systems are used as they best match the absorption peak for water molecules within the ink or coating.

Short wave infrared radiation is most used in drying applications due to the fact it enables high power densities in a relatively small area, as well as rapid cool down times due the lower thermal mass of the heated element.

Due to the fact that the Infrared head radiation can be transmitted to the substrate without the need of an intermediate such as air or water, the energy transfer process is extremely efficient, resulting in much faster drying times and increased process efficiency when compared to air based or other drying methods.

Unlike hot air-drying systems, Infrared radiation is unaffected by the air boundary layer. Passing straight through and into the ink/coating film, it then excites the water and amine molecules within the ink, causing them to immediately permeate and evaporate from the ink or coating film. The intensity of the IR radiation is critical to the penetration through the ink, for this a good reflector design is critical to performance.

Infrared emitters offer efficient heat and much more advantages compared to other conventional heat technologies:

· No direct contact with the product to be heated or dried

· Compact drying area relative to air dryers or gas ovens

· Infrared can we switched on and off in less than a second

· Infrared power settings can be easily adjusted to accommodate speed or substrate differences

· The rapid removal or water and amine from the ink creates brighter more vibrant print.