Sezginler Tekstil realized Zero finishing chemical discharge with TexCoat G4 from Baldwin

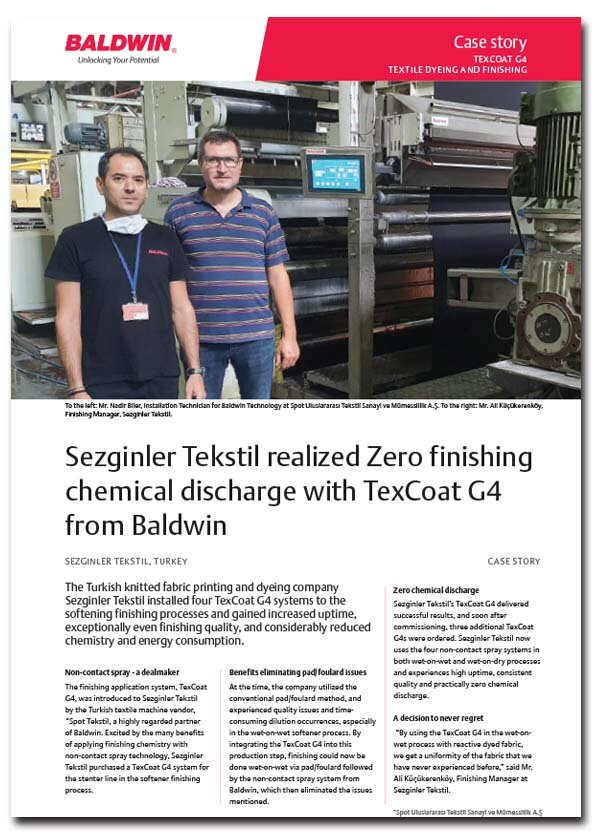

/To the left: Mr. Nadir Biler, Installation Technician for Baldwin Technology at Spot Tekstil.

To the right: Mr. Ali Küçükerenköy, Finishing Manager, Sezginler Tekstil.

The Turkish knitted fabric printing and dyeing company Sezginler Tekstil installed four TexCoat G4 systems to the softening finishing processes and gained increased uptime, exceptionally even finishing quality, and considerably reduced chemistry and energy consumption.

Non-contact spray - a dealmaker

The finishing application system, TexCoat G4, was introduced to Sezginler Tekstil by the Turkish textile machine vendor, Spot Tekstil, a highly regarded partner of Baldwin. Excited by the many benefits of applying finishing chemistry with non-contact spray technology, Sezginler Tekstil purchased a TexCoat G4 system for the stenter line in the softener finishing process.

Benefits eliminating pad/foulard issues

At the time, the company utilized the conventional pad/foulard method, and experienced quality issues and time consuming dilution occurrences, especially in the wet-on-wet softener process. By integrating the TexCoat G4 into this production step, finishing could now be done wet-on-wet via pad/foulard followed by the non-contact spray system from Baldwin, which then eliminated the issues mentioned.

Zero chemical discharge

Sezginler Tekstil’s TexCoat G4 delivered successful results, and soon after commissioning, three additional TexCoat G4s were ordered. Sezginler Tekstil now uses the four non-contact spray systems in both wet-on-wet and wet-on-dry processes and experiences high uptime, consistent quality and practically zero chemical discharge.

A decision to never regret

“By using the TexCoat G4 in the wet-on-wet process with reactive dyed fabric, we get a uniformity of the fabric that we have never experienced before,” said Mr. Ali Küçükerenköy, Finishing Manager at Sezginler Tekstil. “Adding the non-contact spray technology to the pad/foulard, is a decision we will never regret,” Mr. Küçükerenköy concludes.

To read the full story,