Baldwin’s Precision Spray reduces maintenance costs by 100%

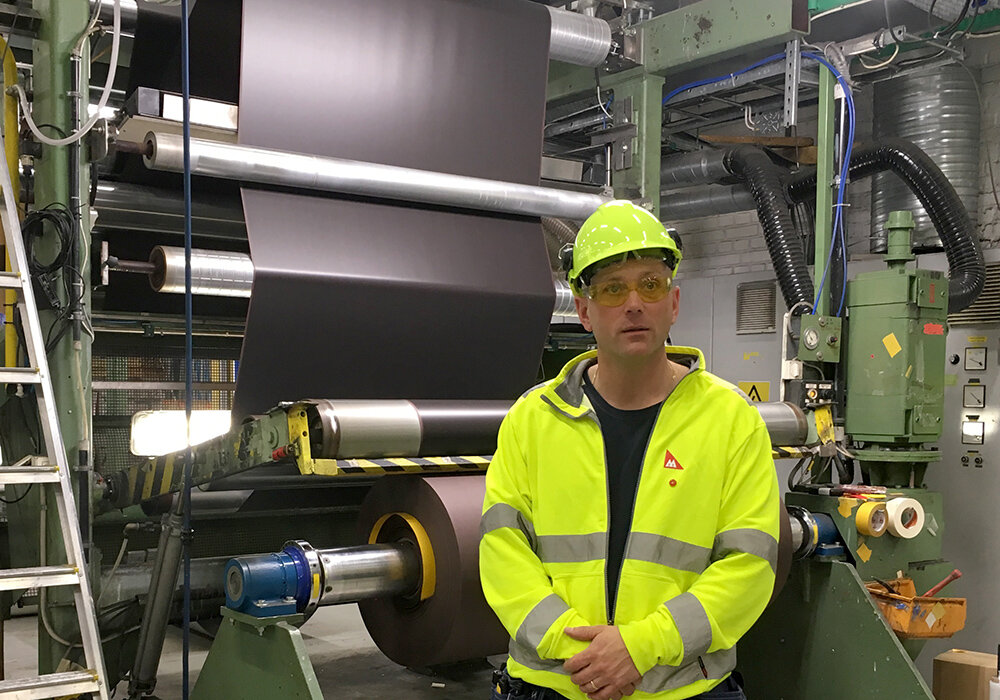

/The world-leading advanced paper manufacturer, Ahlström-Munksjö chose to install a Baldwin Spray Applicator for remoistening in their foil manufacturing process, to cut maintenance costs and reduce downtime and waste. It turned out to be a rewarding choice realizing highly above expectations.

Fast facts

Customer: Ahlström-Munksjö is a global leader in fiber-based materials and manufacturer of advanced paper products in areas ranging from flooring, kitchens and furnishings to release liners, consumer-friendly packaging, medical fiber materials and electro-technical paper.

Challenge: Minimize production downtime due to maintenance of remoistening equipment and increase the end product quality.

Solution: Baldwin Spray applicator for remoistening

Benefits: Saves time – no inspections needed, increased production time, extremely low maintenance, consistent remoistening, saves material costs, continuously high quality with no claims.

Read the complete Success Story here: