As label and packaging printers address current economic situations regionally and globally, especially those predicted to impact operations in 2021, a reliance on technologies that help save resources, from time and energy to inks and substrates, is a key trend as companies determine how to wisely and cautiously invest in capital equipment.

To date, efficient UV and the even-more-efficient LED curing solutions are maintaining their ground in all printing industries, while LED is further gaining favor among packaging and label printers looking to garner the highest quality results, especially on nonporous substrates, while reducing their environmental footprints.

Additionally, ever-more-stringent requirements placed on packaging companies by key accounts in terms of quality and consistency have instigated a need for defect detection and color monitoring, most recognizably in the areas of pharmaceuticals and big-brand food packaging where “accuracy is king.”

Technologies that further efforts towards “food safe, contaminant-free” production also have gained favor among packaging companies looking to future-proof their businesses: LED UV curing is known for eliminating ozone hazards from production environments, while new particle-free electrodes from Ahlbrandt - A Baldwin Technology Company are a prime example of a product gaining importance due to its unique ability to keep production environments clean from accidental contamination.

Finally, Industry 4.0 is driving adoption of Industrial IoT (Internet of Things) platforms that can connect systems so performance data can be aggregated, stored and visualized to improve operations and prevent downtime.

Learn more about key technologies that are helping packaging and label professionals weather difficult markets in our “Top 10 Technologies For Labels & Packaging” list below:

#10

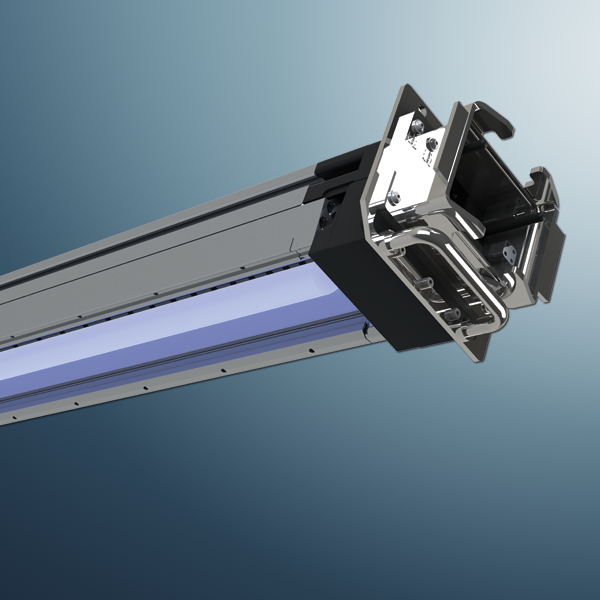

UV Curing by AMS Spectral UV

For those that turn to conventional UV curing for their package- and label-printing applications, especially for coatings and varnishes: Baldwin offers leading ultraviolet arc-lamp-based system solutions for reliable and consistent results, run after run. Utilizing a whisper-quiet, liquid-cooled design, we offer safety and performance advantages over air-cooled alternatives. From narrow to wide formats, our UV systems cover the gamut from labels to flexible packaging.

#9

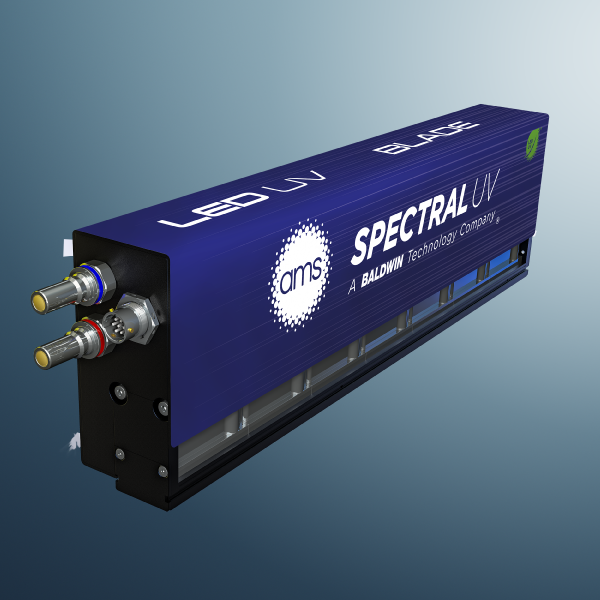

LED Curing by AMS Spectral UV

If you are seeking the most energy-efficient, environmentally friendly solution for securely hardening inks to any substrate - from plastics to metals and all types of packaging and label papers - LED (light-emitting diode)-based curing is today’s choice to achieve great results while using fewer resources. Interchangeable with UV positions, our LED UV systems reduce substrate heat and allow the press to run faster, especially on difficult colors and micron-thin poly stocks.

#8

Guardian PQV by Baldwin Vision Systems

Guardian PQV 100% Print Inspection provides complete print quality verification from prepress through production, reporting, and archiving. Find and remove defects quickly and monitor your processes to prevent defects from occurring in the first place. Guardian PQV delivers the most advanced, automated, inline defect detection workflow for your entire production process.

#7

DeltaCam by Baldwin Vision Systems

Measure, report, and guarantee color quality to your print customers and brand owners image-to-image during the run of your production. While hand-held devices measure only a small fraction of samples, Baldwin Vision Systems offers an affordable, advanced inline spectral measurement solution that will help you achieve absolute color consistency press-to-press, shift-to-shift, even plant-to-plant.

#6

Corona Slim by Ahlbrandt

Engineered to scale from the smallest format sizes to mid-web lines, Ahlbrandt’s Corona surface treatment systems enable easy integration and retrofit in the smallest of working spaces, along with advanced features to diagnose electrode performance and has proven world-class efficiency in most areas of label and narrow web packaging lines.

#5

CleanSpec Electrodes by Ahlbrandt

With a unique particle-free design that prevents metal powder contamination from damaged or broken elements to come in contact with the substrate, the CleanSpec is ideal for clean-room applications, including high-quality food-grade plastic films and packaging manufacturing. CleanSpec provides peace-of-mind, and the electrodes are retrofittable with most systems on the market.

#4

FlexoCleanerBrush by Baldwin

The Baldwin FlexoCleanerBrush offers on-press full-width automatic plate cleaning for flexographic corrugated printing presses. This technology offers fast production washes, as well as the efficiency and safety of fully automated pre-print and end-of-run plate cleaning.

#3

FlexoCleanPick by Baldwin

The Baldwin FlexoCleanPick is a cloth based on-press continuous plate cleaning system for flexographic corrugated printing presses, that allows for long, high-quality, uninterrupted print runs. It allows operators to easily and safely “hickey pick” on demand.

#2

High-Yield Consumables from Baldwin

From leading spray-powder solutions like Oxy Dry, to technical cloth-rolls used for automatic cleaning systems, to UV lamps for precision curing, consumables that give consistent results while minimizing waste are a specialty of Baldwin Technology’s.

#1

Connect These Technologies with AMP

Our Industry 4.0-driven AMP (Augmented Machine Process) IoT solutions from Baldwin Intelligence Group, digitally connects press peripherals and via sensors to achieve data-driven decision making across production processes. Now more than ever, digital access to machines in remote factories has become a top priority. AMP is the only printing and packaging industry data analytics solution that is truly machine agnostic, runs on the cloud, and can aggregate data across multiple makes, models and vintages of machines. All current-generation Baldwin equipment packages - from Cleaning to Corona to UV to Inspection” are connected via AMP to give you a data advantage the moment you start up. AMP your machine today and find out what you’re missing.